THE BASICS OF BUILDING CARS

As with any of our projects it begins with a drawing. Sometimes the drawing is on a napkin, hotel stationery, a sticky note that was handy, or something similar. Next we put the design into a CAD program to work out the size of car and as many details as needed to built it.

In the case of our Gondolas we started with the standard Redwood Valley Railway design by Erich Thomsen and William "Bill" Daney. We then adapeted a few bits of the frame to be fabricated from standard size structural steel rather than require special castings or complex formed parts.

Raw lumber is where every car begins it's life.

Rough sawing the lumber is done on whatever is available and what the boards will fit through.

For these 5" scale / 15" gauge cars a 10" table saw and 13" planer are more than enough to get the job done.

After rough sawing the board are fed through a planer to final dimension.

We design all of our cars around standard sizes. Such as all side and end sills are, per RVRy standards, true 2-1/2" x 4-1/4".

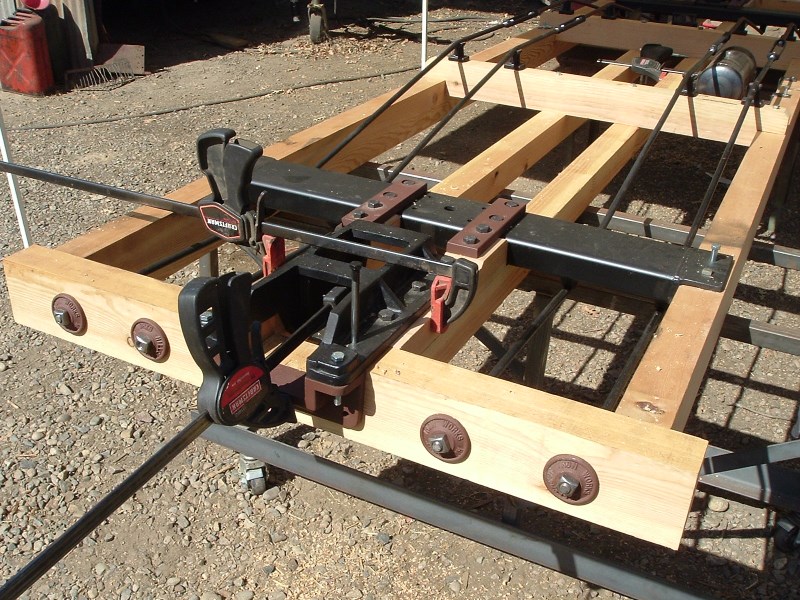

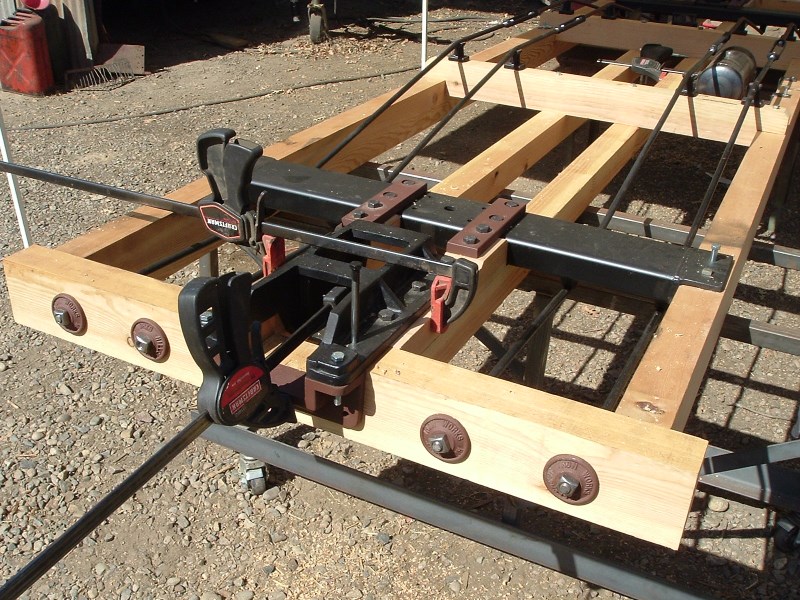

Instead of using Mortis & Tenon joints as was common in the late 1800s and early 1900s we use wooden dowel pins.

No glue is used in the assembly of the car. This allows the chassis to flex with the level of the track and reduces the risk of derailment.

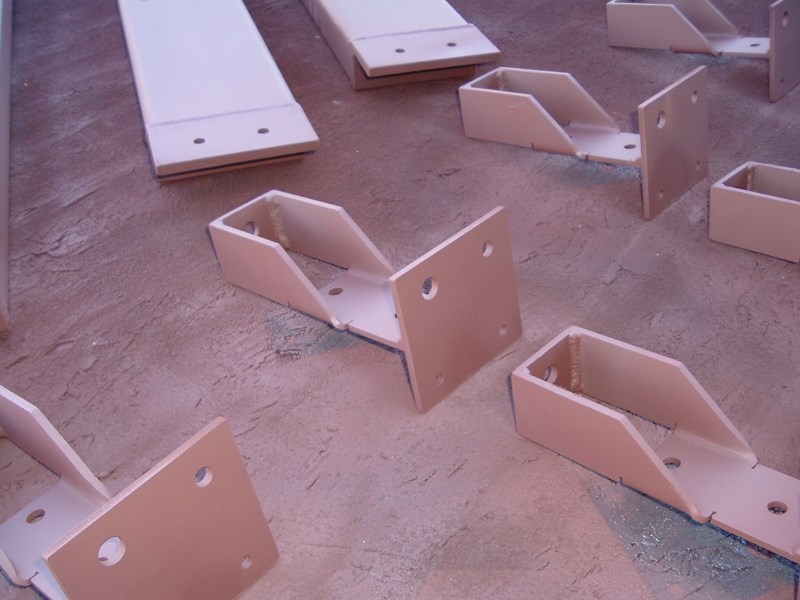

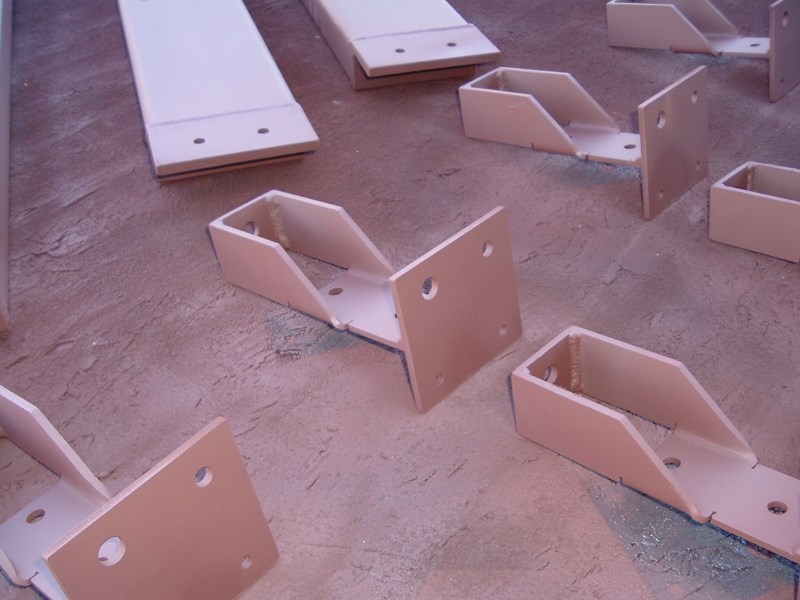

The brake system on the cars is not complex but does have many parts to make it work. These are enough parts for 20 cars.

These are the Body Bolsters which bolt to the wooden frame, and the Body Center Bearings that bolt to the Body Bolsters.

The Body Center Bearing mates with the Center Bearing on the Trucks to keep the wheels under the car.

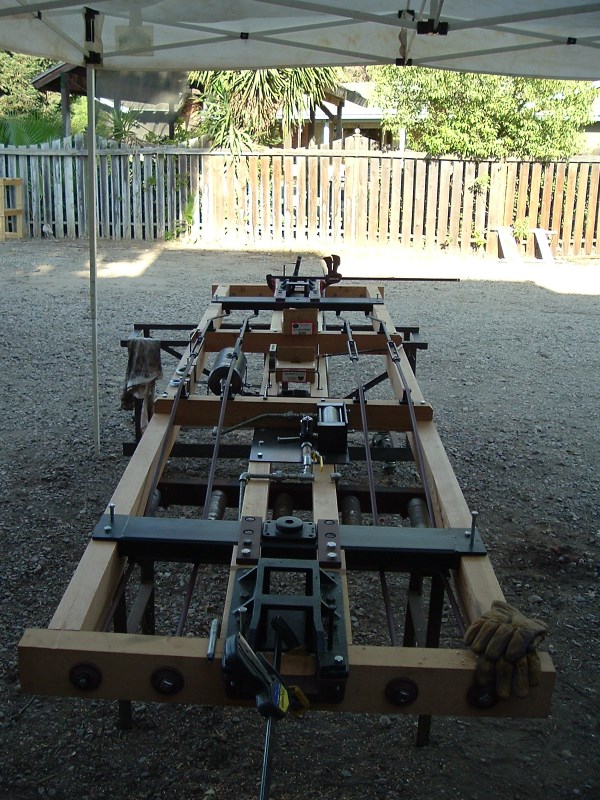

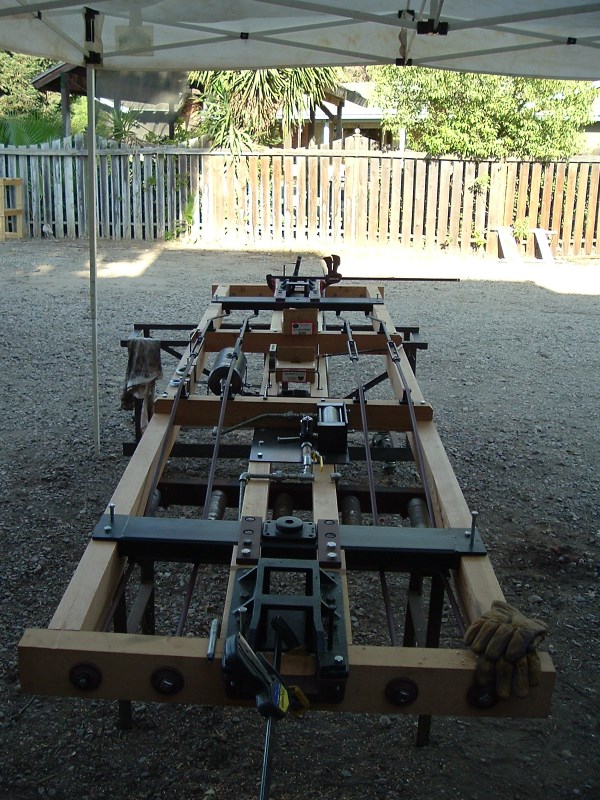

The wooden End Sills, Side Sills, Center Sills, and Intermediate Sills are dowelled together, then the long Truss Rods and the Body Bolsters are bolted in to hold the Sills in place. The cast iron Draft Gear Housing goes on the ends for mounting the Couper and it's Draft Gear.

It's at this stage the final decision needs to be made as to what kind of car is being built. As shown these could be Flat Cars, Gondolas, Stock Cars, or Tank Cars.

The chassis shown in the photos on this page became a mix of Gondolas, two Tank Cars, one Stock Car, and one was cut down for a Caboose.

The chassis to become Gondolas are painted and the sides are build in-place on top of them. As each car is hand built and slightly different, each set of tops is specific to each car.

The chassis to be a Stock Car has a permanent superstructure built onto it.

Most of our cars have these standard Arch Bar Freight Trucks with the brake beams between the wheels, aka "Inside Hung Brakes", underneath them.

Depending on the requirements we have trucks with Outside Hung Brakes or Caboose trucks and Passenger trucks with Elliptical & Coil Springs for a smoother ride.

Here's a photo of Step-Through 12' Gondola #203, 10' Gondola #204, and Stock Car #301