A DETAILED HISTORY

of the

HILLCREST & WAHTOKE RAILROAD AND HILLCREST SHOPS

Hillcrest Christmas Tree Farm is the oldest in the San Joaquin Valley. Founded in 1960 by Ed and Bonnie Toews (pronounced Taves) it has been at its current location ever since. The history of the railroad began with Ed if “fake” trains count.

Some years back before we owned the place old Ed began building a train to move people about the farm. It featured his only and therefore his favorite, tractor with some serious decoration to make it look like a locomotive. Ed built some cars and a caboose on trailers and the first Hillcrest train became operational.

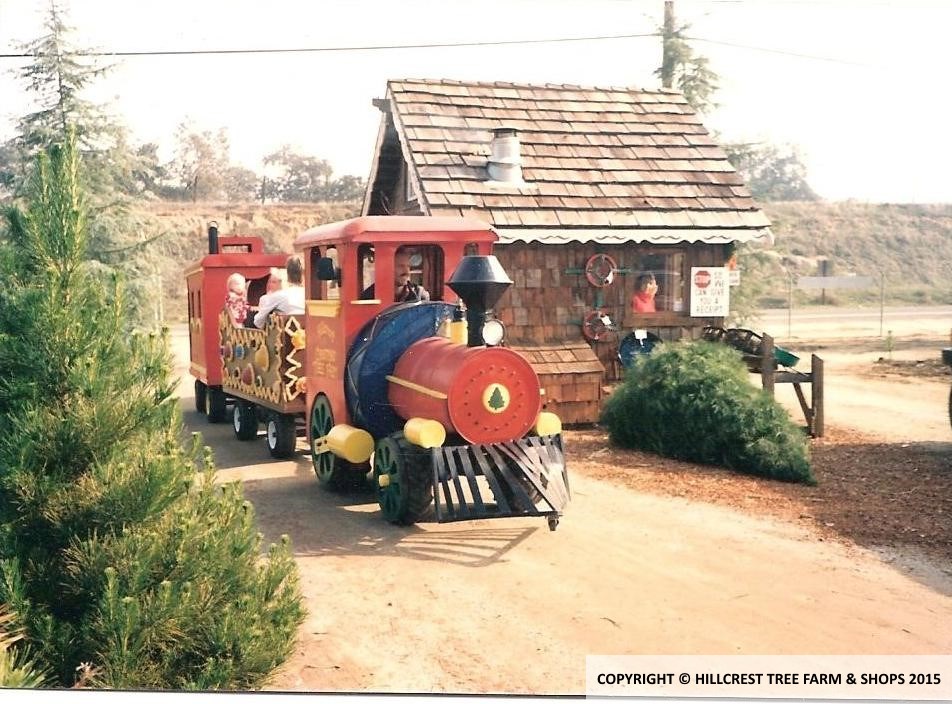

(Left) Ed’s train; A Kubota tractor in costume, near the present front gate.

(Right) Same under construction

This train wasn’t limited to tracks and began running around the whole farm and was featured in some local parades. On the weekends, during the Christmas season, people could enjoy a train for a small fee.

In February of 1992 we purchased the farm from the Toews. A year after purchasing the farm we began to explore the idea of adding a “real” train. Wouldn’t it be cool to lay track to the different fields of Christmas trees and Pumpkins and use the train to bring the trees, pumpkins and guests back to the parking areas? This began our unquenchable thirst to find a train. Several questions needed answering first:

How big does it need to be?

What gauge should the track be?

Will it fit on our land?

How wide do the turns need to be?

Should it be scale to larger trains?

Should it be real steam of fake?

Where does one buy steam trains?

In 1984 while stationed in Texas with the Air Force we discovered an old steam train in an abandoned amusement park in Carlsbad New Mexico. It was straight out of a “Scooby Doo” cartoon mystery. This was some years prior to owning Hillcrest, as a matter of fact this was some years before owning much of anything!

We had inadvertently camped next to the parks back fence the night before. The train was a “Winton” (built by Winton Brown of Oakland CA.) It was two foot gauge of approximately 6” scale. The owner, (we tracked down through asking the locals in the bar across the street) was Pete Pelletier, he had commissioned the building of the train and wanted to sell it to us; on the spot; for a very good price. He told us of its history and how it never ran correctly under steam, he even hired the builder and relocated him to New Mexico just to run it, but the locomotive never performed well so they eventually converted it from steam to diesel/ hydraulic. Being militarily poor we couldn’t afford the $40,000 he wanted for the locomotive, 5 cars, caboose and 1.5 miles of track. It was a bargain even back then, but we just couldn’t spend two years income on a train we had no place for.

(Left) Melissa next to the “Abe Lincoln” locomotive; discovered in the abandoned amusement park. The actual name is Presidents Park, in Carlsbad New Mexico, 1984.

(Right) Lis sitting on the porch of the caboose.

Jump forward now; beginning in 1992, after purchasing the farm, the idea of putting a real train on the property was agreed to. When considering the question of where does one buy a train, we chased the Abe Lincoln down first. It had been years since we talked to the owner. He had since passed away and the train, along with the park, had gone through another owner. The city now wanted to make a go of it and didn’t want to sell. This closed the door to the possibility of having the “Abe Lincoln” run at Hillcrest.

It was probably a blessing that it didn’t end up here. We wouldn’t know so many very nice 15” gauge railroad folks and the Abe had a 200’ minimum turn radius. The curves would be excessively large for our property.

Later that same year while continuing the research (where does one buy a train?) we found a very helpful video titled “Big Little Railways” initially purchased for landscaping and excavation ideas, it became a Bible to finding the right size train for our needs and the experts who could help us with this quest. One of the train men mentioned was Erich Thomsen . After watching the video 100 times, I called up Tilden Park Steam Trains and Eric answered the phone! It was like talking to a movie star, I was humbled. The family went up to visit the park and meet Erich and our long term friendship began. Erich taught us so much over the years, like how to spike track, build switches and he advised us on the purchase of our very first train. Unfortunately Eric passed away in 1995. Since then his daughter Ellen has taken over the railroad and still operates it to this day. Our relationship with the Thomsen family has grown, even after Erich’s untimely passing.

In 1994 after so much searching and bugging people like Erich, Ken Keagy and others, we bought our first “real train.” It was a “Crown” locomotive with 4 cars that had been owned by Jim Adams, Dave Harms and a group of guys in Illinois. We saw the ad for it in the classified section of a railroad preservation magazine. Funny what you can find in a bookstore at the Railroad museum in Jamestown.

This little train had been in several parks over its life time and was sitting on concrete in a barn when we first saw her.

(Left) The Crown before we owned her, notice the high cars. The top to these cars was removed once the train arrived here.

(Right) The first look at the Crown, in the barn in Illinois, it looked like space junk.

The locomotive was manufactured by the Crown metal works company of Wayano, PA. It was their first ever built (serial number 001) and launched them into business manufacturing steam trains, ours was 15” gauge, the smallest size they built.

Melissa and I both broke out laughing when we first saw the engine sitting there. It looked like a piece of space junk that had burned up while reentering the atmosphere and crashed through the barn roof. I think our laughter offended the sellers. We weren’t laughing at the train, or the guys, but at ourselves. The journey to find this “real” steam train had taken some time and many turns, and now here it is, right before us.

“That’s all there is?” I think came out of my mouth. We were laughing at ourselves.

So we bought it. Actually, for the price, it allowed us to get started with the track and layout and begin building the

The locomotive came with 4 cars and 7500 feet of rail. We had to straighten the old rails that had been bent and curved from somewhere in their past. Likewise, we used hammer and anvil to straighten over 4000 used spikes that came with the track materials.

When this project started we knew next to nothing about track installation, so we contacted Erich and the education began. Our first five feet took almost 8 hours to assemble and spike. The going was tough at first. Laying track is loud, hard, dirty, exhausting work. There is no way around it. Each rail weighs 120 lbs and is 30 feet long. All the track curves are pre-bent; all the ties are pre-drilled before spiking. After the ballast is applied and the track lifted, every tie is tamped by hand in 8 places.

(Left) The first rails: starting from the South end of the current tunnel, heading south ward. Notice there’s no ballast and no shop spur.

(Right) The trestle under construction. Note: The driveway had to be lowered 4 feet to allow vehicles to pass under the new structure. The wood came from Cotton Center where we dismantled old olive tanks and is true dimension, heart grain, redwood.

As a mater of fact, our crew flew up to Tilden Park and helped Erich with his trains and track in exchange for advice and the oozing of his great wealth of knowledge. Every time we encountered a hurdle, we went up to Redwood Valley Railway soaked up some priceless information and returned to track lying. The actual track spiking began in July of 1994 and the 1200’ of Hillcrest Loop was completed on November 20, just before we opened for the Christmas season. With Erich’s help and our own experience, we invented some new tools and techniques that greatly sped up the spiking process. By the end of the loop our spiking speed had increased to over 100’ per hour.

This entire time we knew nothing of operating the steam part of a locomotive. None of us had ever done more than put water in a tea kettle. Rolling down the track while building the layout was easy, we propelled the locomotive by putting air from a portable compressor into the boiler and cylinders. Operating a real steam engine was another matter. We turned to Erich who advised us to get in contact with some local enthusiasts to help us learn how to fire up the boiler.

(Left) Crown #1 first steam-up at Hillcrest.

(Right) New livery, headlight and tender trucks for opening day of the H&WRR, Christmas season ‘94

Not being happy with the original red, green, white and black livery of the Crown, we stripped the old paint and repainted her between Thanksgiving Thursday and Saturday when we opened for the season. That almost caused a divorce. I can’t remember the number of passengers that rode the train that opening weekend but I think it wasn’t much over 100. Thus began “real” railroading at the Hillcrest & Wahtoke Railroad.

The Crown had a lot of problems and couldn’t haul more than two cars full of passengers. We used to hide employees in the Christmas trees to help push the train up the hill as it went by. Funny no one ever noticed the first “helper engines”.

Later we completely overhauled the Crown; this necessitated having a machine shop on hand, SOOOO, we began collecting machine tools and making our own parts. The old flocking shed had to be moved and the space used for the lathes and milling machines needed for the farm and railroad.

Installing a railroad is no easy task especially when you are committed to doing it yourself. We realized we needed heavy equipment to just get the dirt ready. A dump truck and Backhoe would be required along with some rentals of skip loaders and bulldozers. I wish it were as simple as the Lionel track I used to assemble as a kid.

Like the old story of the general who lost the war for need of a pen, installing and maintaining a steam railroad required investing five times the work and price of the actual track, cars and locomotive.

(Left) Original flocking shed walls coming down.

(Right) New walls up, note flocked tree in doorway

We never really liked the proportions of the Crown and its cars nor the train’s performance. We began to feel the need for larger equipment, especially with future plans of track expansion. The train is to eventually go from the top of the farm (Hillcrest Station) to the bottom of the farm (Wahtoke Station). Hence the railroads name.

We wanted to build something along the lines of Erich Thomsen's Redwood Valley Railway, scale narrow gauge logging trains in 5” (5 inches to the foot) scale. By scaling narrow gauge locomotives to 5” scale and 15” gauge track, we actually shrink them less than if we were to scale full sized locomotives to 15” gauge. The cars are more comfortable to ride and the locomotives are much larger and can pull more cars.

After 4 years of operating the Crown, a fellow named Clint Green mailed us some artifacts from the trains past. It included old coal clinkers and ballast, newspaper articles, etc. Then he showed up one day. He came all the way from Illinois and offered to buy the engine and cars to send back to Flora, his home town. The Crown (or Little Toot” as they called her) first ran at Flora Illinois back in 1955 in “Charlie Brown” park when Clint was just 5 years old. Now that he and the city managers were all grown up, they wanted the train back in the park where it all began. The price was right so we had to say “goodbye Crown.” Parting was tough, with so much time, sweat and money invested. The Crown had got the H&W going.

With the proceeds from the sale of the Crown we began designing and fabricating the tools necessary to make our own cars. We decided to make all the similar parts interchangeable in case we ever decided to sell these to potential customers. Little did we know then what would eventually develop and this proved to be a smart move. Hillcrest Shops was born! (See shops history) The development of the tooling and construction of the first car began in 1997 and finished in 1999.

With no locomotive to pull the new cars, we needed an engine before Christmas. Just as things happen, another railroad of 15” gauge and 5” scale lent us their “Shay” for a year if we would repair her boiler and firing issues. The engines boiler needed to be re-flued and the burner needed to be a bit larger so we made the required repairs and started operating the Glenwood Southpark and Pacific’s #7, a two cylinder, two truck, class A, Shay locomotive. The engine was built by Ken Kukuk of Los Angeles and is a real beauty.

We can’t thank him and the Glenwood gang enough for all their help!

GSP&P Shay #7 on the left with the Crown on the right just before it left the H&W

Construction continued on more new cars and by 2001, 5 fresh cars existed including # 301, the new stock car. This car was unique because it was our first designed with automatic air brakes, or any brakes for that matter. Because we started by making all car parts interchangeable, we were able to retrofit the previous built 201 and 202 cars.

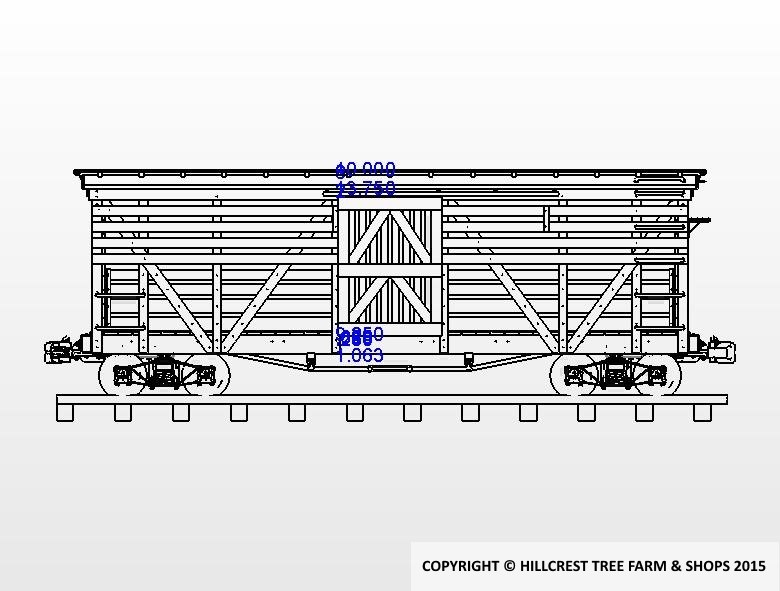

(Left) Our computer rendition of the 301 car.

(Right) building the car in the shop with the train night gang.

(Left) The finished 301 car, note the brake hoses.

(Right) Cars 201 and 203. All cars (except high cars) convert to flat cars if needed. #203 is carrying the wheel sets for next series of cars to be built.

We returned the Shay to Glenwood and inherited the #2 “Shaun” from Bill Fahey. This engine is one of the oldest ever used at Hillcrest. Its history prior to 1938 is vague. From what we know it began life around 1917, was reboilered in 1938, overhauled in 1996 and came to Hillcrest in 1999.

(Left) Bill Fahey’s #2, the “Shaun” pulling our new cars with a full load up the tree house grade.

(Right) New gondola chassis being assembled upside down.

This engine is an “American” 4-4-0 wheel configuration, like the Crown. It featured a “Briggs” dry firebox boiler and a working steam pressure of only 100psi. Though small in stature it pulled hard and we ran this locomotive until 2001 when the 2-8-0 Consolidation arrived. Currently the Shaun locomotive is awaiting shop overhaul and outfitting.

The late Frank Allen from Orland, CA who built the beautiful “Sonoma” orchestrated the loan. He knew we were in need of a locomotive and the maintaining of two steam engines was too much for him. Frank brought the locomotive all the way down on his custom locomotive hauling trailer.

(Left and Right) Pictures of Frank Allen’s “Sonoma”. This was modeled after the narrow gauge locomotive featured in the lobby of the California State Railroad Museum in Sacramento. A regular at the Reedley Rail Fest for the last two years, it now belongs to the State Museum.

Not long after receiving the #2, Ken Kukuk of the Glenwood South Park & Pacific railroad finished building his 2-8-0 “consolidation, the #13. 7 years in the building, the locomotive was ready for testing. Not having a loop to continuously run on he asked if we would bring the locomotive to our track for its initial fire-up and test run.

There were the usual gremlins and quirks to fix, like its tendency to light the track on fire. We worked on it all day and into the night. Ken left that evening saying “let me know when it’s a good engine” He had really built a beauty and in a very short time she was running great.

We told him his locomotive was perfect, but the engine has never made it to its home track. It has lived here ever since. Ken is very generous! What a guy, without him we never would have been able to grow.

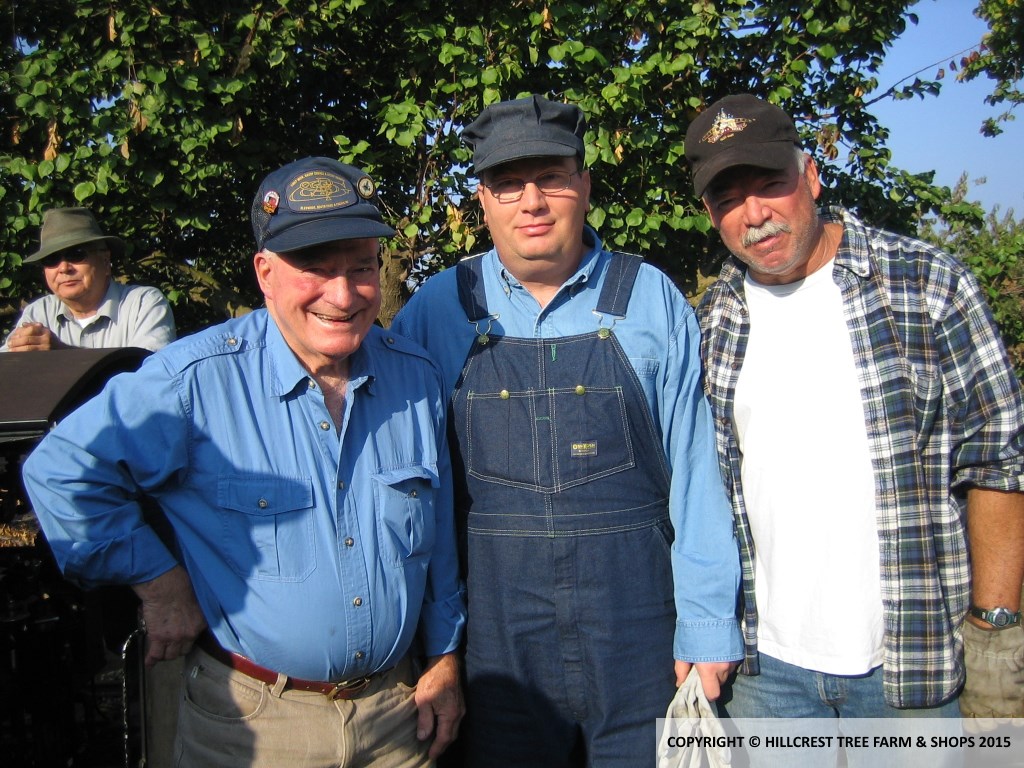

The Glenwood gang can often be seen here, especially come October during Reedley Rail Fest.

(Left) The Glenwood #13 loading passengers at Hillcrest Station.

(Right) GSP&P crew meet Engineers from (a famous theme park in Anaheim CA.) Bill Trail and Jim "Homer" Holmes from GSP&P are on the left, Dale and Craig are on the right. Picture was taken at Reedley Rail Fest.

The #13 is equipped with a steam powered air compressor to operate both locomotive (independent) and train air brakes. After building the 301 to be compatible with air, we retrofitted the #13 to match the type of airbrakes (automatic) we built into the 301 car. The new system proved so successful that we retrofitted the previous built 201 and 202 cars. All cars built since then have the automatic air brake installed. The system works backwards of what most people think normal. If the air in the brake pipe is lost, the brakes will automatically activate, and they apply using the same air. The system has only one moving part and no springs! It’s almost bullet proof.

After 201, 202 and 301 were built we finished the 203 and the 204. The cars are numbered for the series or type of car and the specific sequence in which they are ordered. For example; all Gondolas are 200 series cars. 201 may be built after 204, but it was ordered to be built first. 203 was our prototype “step through” gondola car. It too was a hit, especially when getting in or out of it. # 204 was built for the GSP&P but, like the #13 has yet to make it there. It too is special because it is the only remaining prototypical gondola (normal sides) and it is a ten footer, two feet shorter than a typical gondola. All the gondolas built since 204 for the H&W are step through “gons.”

Gondolas 205 through 208 went to a customer in southern California in kit form, 209 went to John Ray near Gilroy, was bought back later in partial kit form and was actually built here. Cars #210 and 211 went to the ATT&NW Railroad in Missouri. #212 through 215 were built by us for the H&W. #216, 217, 209 and 220 were the latest built in 2008, again, for the growing needs of the H&W. # 218 and 219 were built for another customer in Arizona.

(Left) The 219 gondola in Arizona. Note the link and pin couplers and no brake hoses.

(Right) the LGB model of the Davenport 0-6-0, outside frame switcher, kit bashed to represent the future #57 locomotive for the H&W.

It wasn’t as though we spent all of our time building gondolas and running Kens engine around the 1200 original feet of track. We had BIG DREAMS with greater men and women dedicated to making them come true.

We began designing a switcher locomotive back in the early days to be a backup to the Crown and a general all-purpose work engine. We liked the 0-4-0 Davenport locomotive of the Denver and Rio Grande R.R. fame, but since this type had been built in 5” scale already, we wanted something more unique. Davenport locomotives had elements of both the new diesel world and the old steam era. We found that they had exported 6 wheel locomotives much like the beloved 4 wheel locomotive; but with some newer refinements and 6 wheels. We couldn’t find any drawings, just a few photographs were all that existed so we modeled ours using Davenports original full-size drawings of the #50 locomotive and an LGB, “G” scale, electric train engine for proportioning.

What started as a simple switch engine became a full-fledged diesel powered monster. The locomotive took three years to build, weighs over 5000 lbs and features a 4 cylinder, Nissan 40 hp diesel engine, hydrostatic drive, working sander, both independent and automatic air brakes, and a working air supply for track and bridge maintenance.

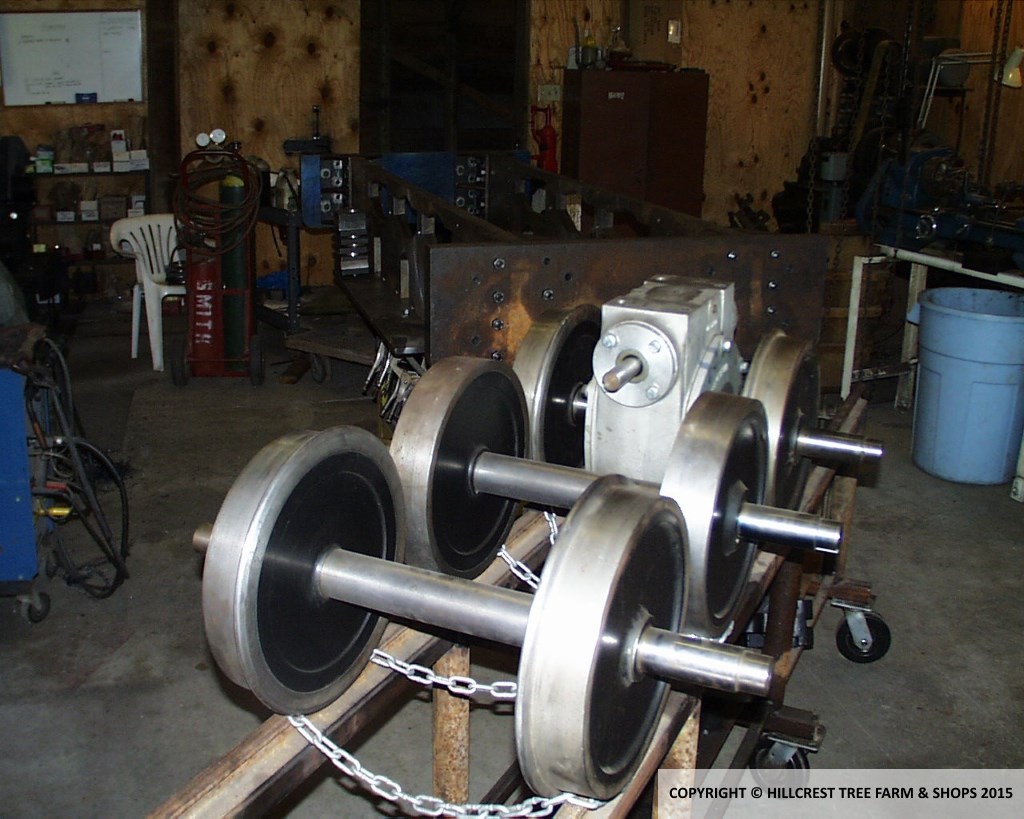

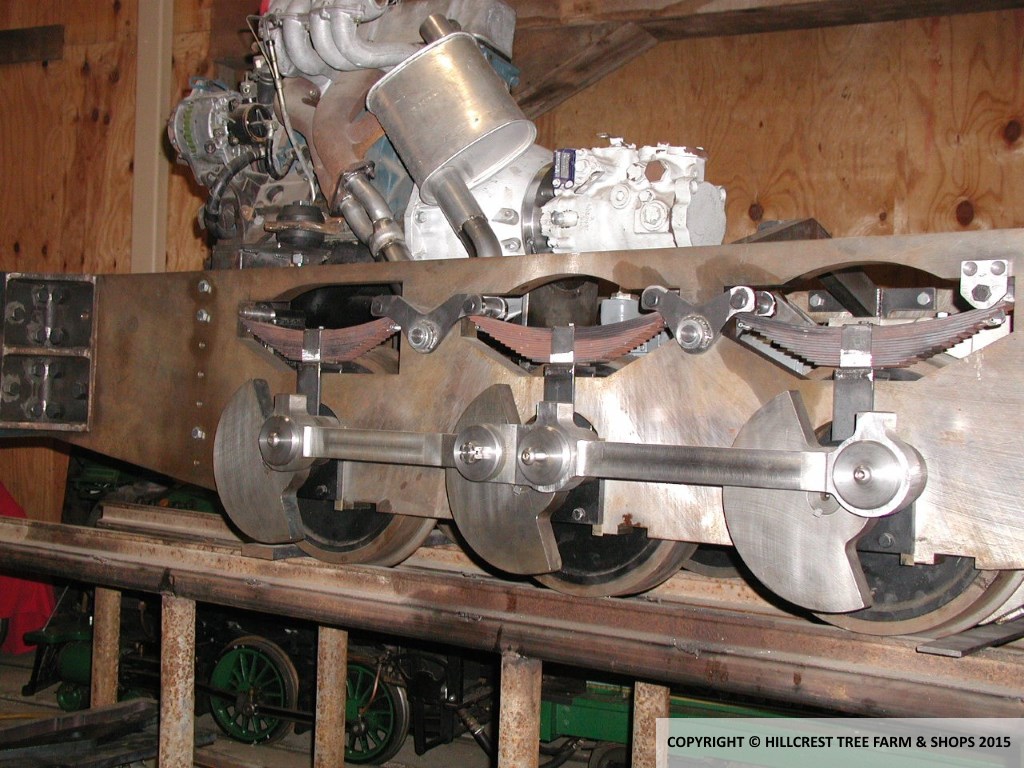

(Left) Wheels, axles and gearbox are finished and partially assembled.

(Right) Wheels sets are finally assembled with counter weights and side rods. All are machined from billet steel. Note the engine, pump, suspension and chassis are in place.

(Left) Chassis reassembled after paint.

(Right) Rodney in the cab, # 57 under construction. Note no headlight or bell

Chris Allen is busy lettering the #57. It takes a steady hand!

(Right) The finished product after years of work. Note the bell, whistle, headlight and side rods are all of the steam era.

In 1999 negotiations began with our neighbor Fred Smeds to purchase the adjoining 20 acres of land immediately to the south of our 5. Ten of these had been leased by us for years. Even before we owned the farm, this land had been leased and much of what the public knew to be Hillcrest Christmas Tree farm actually belonged to the neighbors. This sale provided the opportunity to expand the railroad and the tree farm. First things first; we needed to get track past our driveway

(Left) The grade crossing tracks for the main driveway are pre-built at the shop.

(Right) The crossing installed across the main driveway. This allows the Railroad to cross the driveway onto the new 20 acre land. The crossing was installed by a crew (or better a party) of dozens. Great preparation and a large gang make work seem easy. It took about an hour including the paving!

...and onto the new land.

After the crossing was in place the rails had to be joined from the existing Hillcrest loop to the crossing and eventually beyond. New switches necessary to tie in the track had already been cut in by the “train night gang” some time before. The amount of work needed to get to this point was immense. For example, half the trestle had to be dismantled and rebuilt to accommodate one switch.

(Left) Under the Walnut tree; Ken Kukuk and Vic aligning the new track from the crossing back to Hillcrest loop and the new switch.

(Right) Mike Morosolli pushing out the vines to Make room for the railroad and Christmas trees

After the purchase was finalized, we pushed out the existing vines and began the grading for the “CUT” and the new road bed, two 30 yard scrapers, a bulldozer, a road grader and two water trucks went to work. The dirt removed was used to build the 4 foot high berm surrounding the property and the 18” high berm lining the cut itself. All the top soil went to the bottom of the farm to back fill the large circular planter that will become the road bed for the return loop of track at Wahtoke station.

Why make such a huge hole in the ground? The “cut” is necessary to get the track to the bottom of the farm. Trains typically don’t like steep grades. The grades that automobiles consider normal (5%+) are excessive to a train. The design we came up with is a compromise. The decision is between the ability to haul the greatest number of cars with the least amount of maintenance versus the cost of removing that much dirt. The breakeven point was to keep the grade to the bottom at 1.5% or less if possible. In order to keep the grade this low, the descent needs to start at the far Western edge of the upper property and continue all the way until reaching Reed Avenue at the south part of the bottom land.

Over 1500’ in track length is necessary to descend the 24’ in altitude between Hillcrest station, up top, and Wahtoke station, down below.

(Left) Grading begins on the upper ten acres for the large 10,000 cubic yard “Cut” Several crews worked for weeks to finish the work.

(Right) Looking from East to West, the Cut is getting deeper. This reminds me of the beginnings of the American cut of the Panama Canal.

(Left) Still the cut gets deeper. Though not near finished you get the idea. After the first section was excavated, the bottom of the drainage portion was removed leaving the elevated roadbed shelf that the track is laid on.

(Right) The lower parking area and beginning of the road bed for the Wahtoke loop. This will be the future lower terminus for the trains.

10,000 cubic yards of material were removed from the fields and used as berms for landscaping and flood control. The “train night gang” began the design of the railroads extension on napkins and placements during dinner. Soon we had the entire project converted to digital with topographic features included.

With the field cleared of the old vineyard and the earth removed it was time to grade the roadbed and the train barn pad. Work began in earnest and even the neighbors came over with their tractors to help. With the road bed prepared we began the long process of laying new track. Our plans were on a large scale.

(Left) Digitized version of our napkin drawing showing the track layout in green. This design wasn’t used, but shows all the topo features of the farm.

(Right) Dave Kope and the #03 Speeder on the crossing, between the old original Hillcrest Loop and the new 20 acres. Note the vines are gone and the tracks stop at the end of the asphalt. The cut hasn’t started yet.

As with any big idea project, either you need to have a lot of money, or other people willing to invest their money, or a lot of friends that like to work hard. This railroad wouldn’t exist without the later.

To help get dreams realized, car projects built, track expansion, repairs and training accomplished we organized “train night” and work weekends. Train night happens one night a week, usually on Wednesdays, while work weekends occur once a month. Friends come from as far away as Oregon and Los Angeles to help on these weekends.

Before progress could be made on the other (south) side of the crossing, switches would be needed. Like the proverbial question where do you buy locomotives and cars, where do you buy switches?

I remember buying switches or “turnouts” as they are technically called, when I was a youngster, for my family’s HO train set. You could just go into the hobby store and pull the size you needed off the shelf. They had numbers associated with them, which I didn’t understand then. A number 4, for example, means that the turnout deviates at a ratio of 1:4. Similar to how house roof pitch is numbered. The turn deviates out from the straight portion at a ratio of 1 inch deviation for every 4 inches of run. The new track required that we calculate the turnout number needed and build the switches to suit.

With no switch stores available, we began fabricating the custom (non rail) components of the switches. In front of the shop an assembly line was created and production started on the turnouts.

We began building the new switches in earnest. The predominant sizes are #6’s, #8’s, and one number 12. The first thirteen were for the H&W and another 40 or so for customers and friends. Ours were stacked on a trailer, pulled by tractor to the new field and then were literally placed on the ground, where they were to go in the lay out. Because the train night gang (TNG) had digitized the project, the switches could be located very accurately in the new field. Track was then laid to connect the switches and before you knew it, the railroad expansion was off and running.

(Left) New track, the beginning of the expansion., The crew is tying in the new track to the existing loop by laying the track from the crossing backwards to the switch. Note: The crew pictured is a mix of Hillcrest, Glenwood, and Redwood Valley railroads.

(Right) New switches, #6 and #8, preassembled at the shop for the track expansion, are being fork lifted to a trailer before setting them into the field.

Between work weekends and train nights the track was laid all spring and summer through the new field. We began in February when it was cool, but it was not uncommon to go through 10 gallons of “gator aide” in one evening while spiking track in 105 degree heat during the summer. Grand Scales Quarterly Magazine wanted to have a convention on the West coast in October of 2003. Greg Robinson, the then owner and editor called and asked if we would host it here at Hillcrest. With that deadline approaching (of course we accepted) we were busy all the way up to the opening morning working on the track and the new train barn.

The weekend before the convention we had set a spiking distance record, which I believe, still stands to this day. The work weekend crew laid 1500’ of track in a single, very long day.

Along with the track, many other things needed to be designed and built including the train barn, with its special three-way stub switch, two new bridges and the switch throw mechanisms (or harp stands.) for all the new turnouts. This added work to the already busy schedule.

Once the track was spiked and aligned, the crew covered it to the top of the rails with crushed rock (ballast.) Then the rails, ties and switches are lifted through the rock a couple of inches and the ballast is tamped under the ties. This is how the track is leveled both length wise and side to side. Following the tamping (remember at 8 places per tie, the rock is packed, by hand) the track is dressed with shovels and brooms to look nice. The Hillcrest gang with the help of many other railroads were tamping track up to the last second.

First rails of the new track being spiked. This section is the mainline track through “Pine Tree”. The switches at the West end are already in place and the crew is connecting this track between sets of switches. Notice the cut on the left. Spikes are driven in using air hammers

(Left) Work weekend crew finishing up the details on the train barn.

(Right) The train barn from across the cut. Note the track isn’t spiked in the actual cut.

A golden spike ceremony was held at night when the final spike was driven into the new track extension. Melissa being the real boss was given the honors.

(Left) New switch is on the ground and rails re-joined to it in preparation of spiking. All rails have to be pre-bent before spiking due to our relatively tight turn radiuses and large seasonal temperature variations.

(Right) Work Weekend crew is ballasting the “wye” and the beginning of the Wahtoke division.

Following the convention of 2003, work progressed on the railroad to bring the much-needed irrigation to the new property. This allowed both landscape and Christmas trees to be planted. Our goal has always been to reach the Christmas tree fields with the train and bring back the cut trees on the train with the guests. The railroad extension was designed to facilitate this plan. Hillcrest Shops became busier also and new track of larger gauge needed to be added. In 2005, 800’ of three foot gauge track was installed at the south end of the property. In 2006 a single rail was added to a section of this, making it dual gauged with both 2 and 3 foot gauges.

In 2005 The Grand Scales Quarterly asked if another convention could be held here. This time things were different and a lot of new ideas were incorporated that have become part of our regular season attraction. In October our Pumpkin season opens with a special event called “Reedley Rail Fest”. This is a carryover from the GSQ conventions . It coincides with Reedley’s Fiesta celebration. The railroad invites people and their trains from all over the western USA to participate. Add in live music, good food, antique tractors, cars and stationary engines and the railroading fun begins! Because of the added dual gauge track larger locomotives participate as well. It is not uncommon to see 10 steam trains running, at the same time, on the same track plus diesels, speeders, stationary steam and gas engines from G scale to three foot gauge.

The new layout design required some other less tangible improvements. This size of layout, being essentially single track, with the number of sidings, wye’s, switches and the long steep grade illustrated the need for additional crew training. We used to operate without train brakes (this is not uncommon, even at public parks) but the long grade required that we install them. None of our crew members were familiar with automatic train air. Whistle signals and hand signals all have specific meanings, radio procedures and switching cars needed to be standardized.

Pictures from Reedley Rail Fest, opening Pumpkin season weekend in October.

Beginning back in 1994 after our Christmas season was over, Michael Freidenberg, one of the original Hillcrest engineers, developed the idea of adding another season to help utilize the farm and the new railroad. Fresno County was developing the “Blossom Trail” as a tourist attraction to help spawn “Ag-tourism” and “Value Added Agriculture.” At the time and Hillcrest became a featured stop on the trail and a poster farm for both.

With spring fever a lot of folks are looking forward to getting out of the house. Blossom trail is our third season for opening the farm and railroad to the public. Many social clubs, car clubs and tourists stop here on their outings along the Blossom Trail.

Pictures from Blossom Trail in March. Custom cars from one of the many clubs that stop to ride the Hillcrest & Wahtoke

Through the help of John Bishop, our resident professional engineer, the Hillcrest & Wahtoke Railroad began an extensive training program overhaul. Though invisible to the guest’s eye, this was the largest, most extensive improvement to the railroad in its history. Training syllabuses had to be written. Rules of the railroad had to be published; maintenance logs had to be started. Standardization of evaluators, tests and performance guidelines all had to be created. The process to become a fully rated steam engineer through the H&W system is a serious and lengthy process. To date there are 10 certified steam engineers and 2 diesel engineers that can haul the public.

(Left) Diesel 101 training during a work weekend.

(Right) Switching training using two trains. Notice Mike to the right with his hands in the air. He is signaling the green diesel locomotive. Cars are set out all over the railroad and crews have to put them together in specific sequences using standard operating procedures.

More is on the way as we continue to develop the history of the railroad. This text may change as we update and revise the railroad. Coming Soon will be the finishing of the cut and the installation of the riveted bridges. And the building of the tipple.

It’s been a few years so time to catch up with the goings on of the Hillcrest and Wahtoke Railroad.

5 more acres were added to the site in 2010. This incorporated the old Smeds packing shed, cold storage and homestead. The facility for making trains moved to the revamped packing shed. The roof was raised 4 feet, walls were erected and a new crane and service pit were added. Now we finally had the space to build our trains properly.

THE NEW SHOP

(Left) Finished concrete over the crane piers.

(Right) The holes are 7 feet deep, those bolts at the base are 5 ½ feet long and a cage of heavy rebar surrounds each. These columns are 12x12”, steel and 5/8” thick. Tese support the runways that the bridge crane travels on.

MORE HISTORY COMING SOON (FALL 2015)